High-performance carbon

and linen composites

short-run molds, carbon fiber, carbon, biocomposites, flax composites, Kevlar, aramids, fiberglass

Laminate prototypes

We offer the creation of a finished product prototype, which can consist of metal parts, composite parts, and incrementally manufactured components. Additionally, we serve as an intermediary for contacting certified units for strength testing of prototypes.

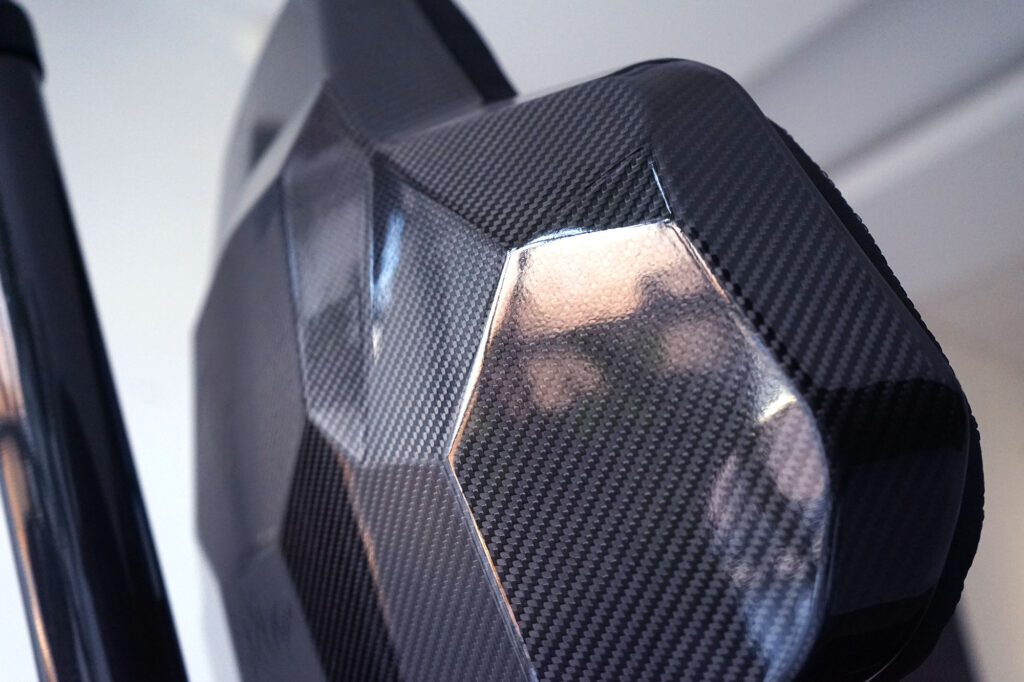

Carbon laminates and composites

If you need carbon fiber components made with the highest precision, look no further! We are the perfect partner for the job. For nearly a decade, we’ve been creating composites that set new standards for strength, lightness, and resilience in a wide variety of industries – from medical and automotive to aerospace, sports, and defense.

We are with our customers every step of the way – from CAD design to functional prototyping, strength testing, and production optimization and scaling. With our state-of-the-art machinery, innovative production concept, and well-trained employees, we produce components that meet the highest quality requirements.

Natural fiber composites

In order to meet the increasing requirements for reporting and reducing greenhouse gas emissions, as well as trends indicating a significant increase in interest in environmental responsibility, we have decided to add flax fiber biocomposites to our portfolio.

Replacing carbon fiber with flax fiber significantly reduces the cost of the composite while maintaining the same high quality standards. Flax biocomposites offer a unique combination of high strength, low weight, excellent vibration damping properties, and thermal and acoustic insulation.

Biocomposites are used wherever the combination of strength and lightness is critical and the ecological nature can provide a competitive advantage.

Kevlar laminates and composites

Kevlar is a superior alternative to carbon fiber due to its enhanced ability to absorb impact energy and its exceptional resilience to dynamic loads and cuts.

Kevlar composites offer a distinctive combination of strength, lightness, and resistance to a multitude of external factors, including impact, abrasion, high temperature, and chemicals. These exceptional properties make Kevlar composites an indispensable material in a diverse range of industries, including protective, automotive, aerospace, and sports.

Kontakt our specialist

Zuzanna Murek

Research and Development Engineer

zuzia@cosmotech-3d.com

+48 880 888 899

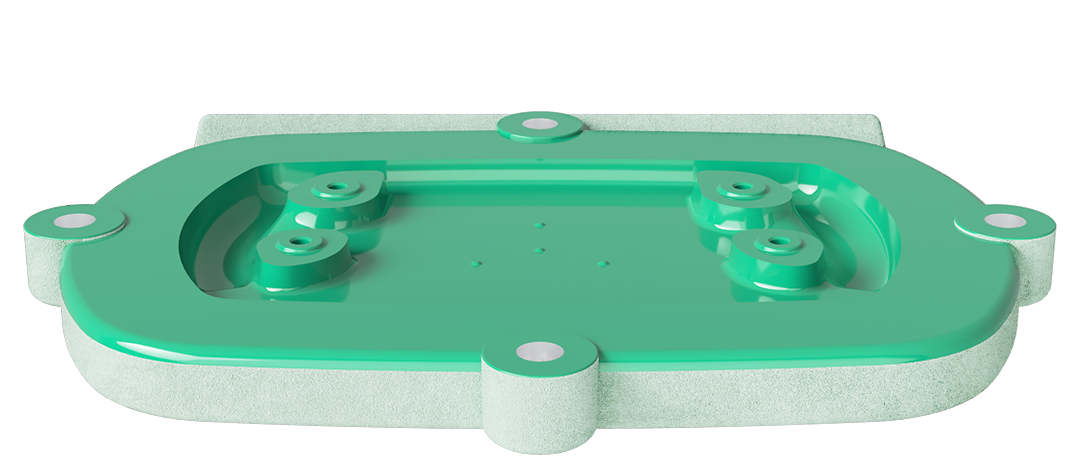

Short-run Molds

We offer comprehensive mold design and manufacturing services for short production runs or to test the shape and functionality of parts before investing in expensive metal molds.

We have developed proprietary technology to produce high quality molds using large scale 3D printers. Turnaround time for a single mold ranges from three days to three weeks and can save up to $80,000 by catching design errors before metal molds are ordered.

Reproduction and Copying Services

Based on a customer supplied component of any material, we offer the creation of a carbon fiber or other laminate copy. If the required quantity exceeds several pieces, we also prepare the production process.

Q&A

What are flax biocomposites?

Biocomposites are polymer composites in which at least one component is biobased or biodegradable. In the case of flax biocomposites, the component is typically flax roving fabric, a material comprising high-performance flax fibers and a weave comparable to that used in carbon parts.

What is carbon fiber?

Carbon fiber is a composite material made of ultra-thin carbon fibers that offers unparalleled strength, light weight, and high temperature resistance. These properties make it an ideal material for a wide range of applications.

What are the disadvantages of using carbon fibers?

The main disadvantages of carbon fiber are its high production cost and brittleness. Despite its high tensile strength, it is prone to cracking under impact. As a result, we use Kevlar composites in applications subject to impact, dynamic loading and cutting.

What is kevlar?

Kevlar is a synthetic aramid fiber that offers unparalleled strength, light weight and heat resistance. It is a key material in the manufacture of bulletproof vests, helmets, and high-impact and abrasion-resistant components.

Are flax biocomposites biodegradable?

The biodegradability of a polymer matrix depends on the material used. Traditional matrices such as epoxy resins are biodegradable, but the matrix may need to be recycled. We offer a range of biopolymers that can be tailored to meet customers’ environmental requirements.

What are the production costs of flax biocomposites compared to other materials?

In terms of material cost, flax woven fabrics are less expensive than carbon woven fabrics, but more expensive than glass woven fabrics. However, the production cost of flax biocomposites varies depending on the desired strength parameters of the composite, the type of polymer matrix used or additional finishing processes. Our engineers are available to assist you in selecting the optimum solution for your project.

Can Kevlar and carbon fibres be replaced by flax biocomposites?

No. Flax biocomposites are a good alternative in some applications where stiffness and lightness are required. However, Kevlar fibers are better for impact resistance, and carbon fibers have better thermal properties.

Can flax biocomposites be mixed with other materials?

Flax biocomposites can be mixed with other materials to make hybrid structures with different properties.

That’s what we’re proud of